Our projects are based on a synergy between time, people, and nature. With a bent towards change when it contributes to improvement.

Woodworking, as we understand it, is a step perfectly fitted in the value chain, which integrates supply chain processes in a smart and sustainable way. Partnering with our company to turn your design and furnishing ideas into reality means supporting a new way of managing the raw material procurement process of acquiring the raw material. It also means shaping wood products with advanced construction techniques and the best raw materials.

How do we make this possible?

We eliminate waste

In wood processing and transformation, we almost obsessively try to reduce any kind of waste in raw materials and process scraps alike. How? We produce exactly what the customer needs, thus reducing the delivery times and enhancing sustainability.

The customer is a value

Throughout the creation and production process, we always put ourselves in the customer’s shoes. Our approach is based on care, listening, and trust. Each customer is different, so we customise the process to meet every request, supported by our strong organisation and a highly specialised team.

Continuous improvement

We are not afraid of change, especially if it contributes to growth. We keep on improving our production processes with a scientific approach by raising standards and ensuring sustainability. All our choices are geared at increasing the quality of service, each of us contributing their own ideas and proposals. All members of our team are involved in this change-oriented process and are focused on it.

The Kanban method

WHY DO WE USE IT?

WHY DO WE USE IT?

We use this method to increase the efficiency of the raw material procurement and replenishing process. The necessary raw materials are supplied at exactly the right time for production. The ultimate goal is to align production capacity with demand, thus avoiding both overproduction and unnecessary waiting times between consecutive processes.

What are the advantages?

- It shows the work progress and helps constantly monitor each stage in the production and procurement cycle.

- It prevents the formation of bottlenecks.

- It is a system for monitoring production and materials available in the logistics network.

- It avoids overproduction and extra stock, which contributes to recovering storage space.

- It helps us fulfil the customer’s demand precisely.

- It is sustainable: it only takes what is needed from nature.

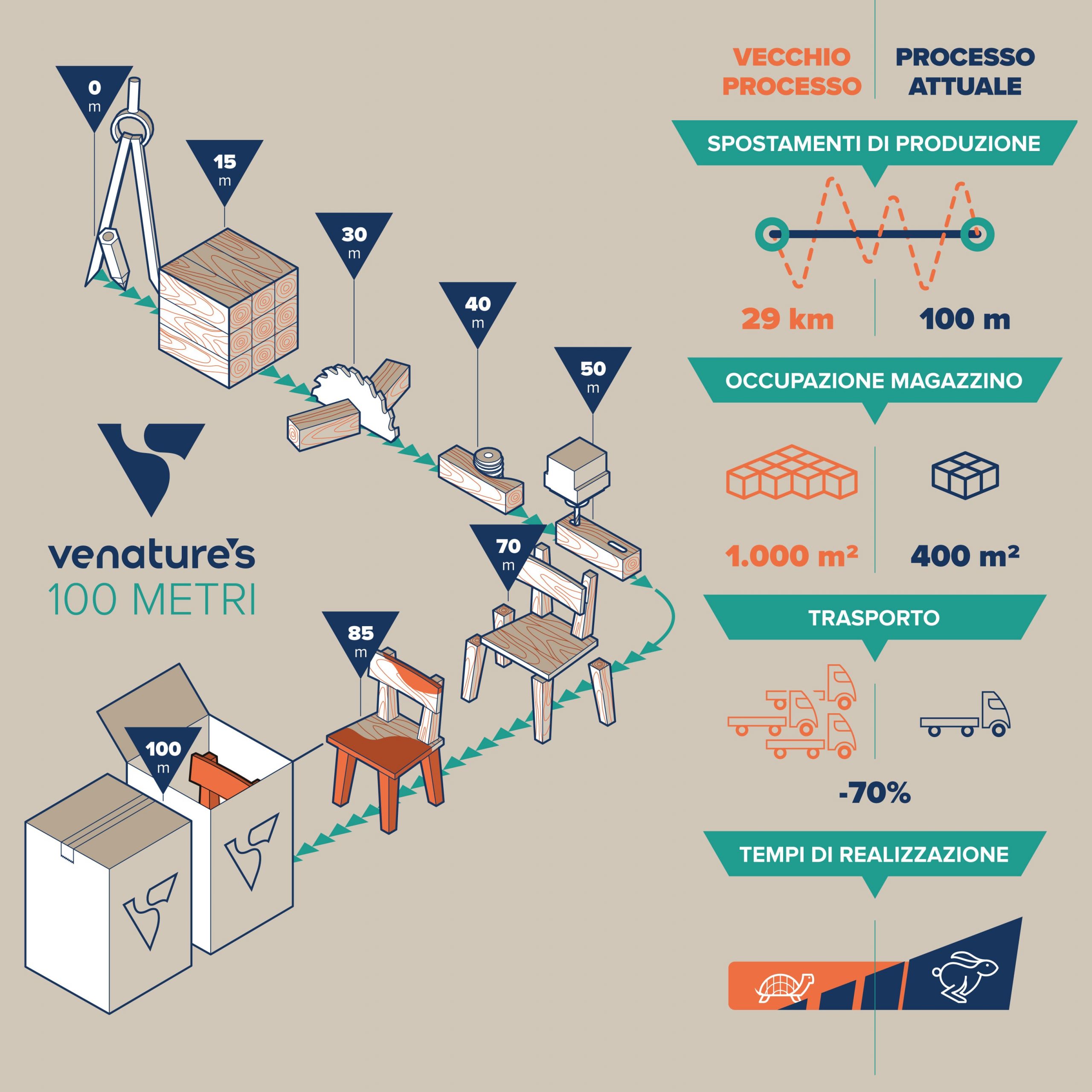

Venature's 100 meters

This is a number we are particularly proud of. From product design to finishing, our production process develops in exactly one hundred meters, no more and no less than that. This distance used to be kilometres in the past, around thirty. Now, our optimised production system implemented through the rationalisation of each step in the process has helped us save a lot of meters, i.e. less time spent going to and back from the warehouse. How has this achievement been possible? We have completely revised the production layout and worked hard to optimise the setup times.